Your Pulling a vacuum to 500 microns images are available in this site. Pulling a vacuum to 500 microns are a topic that is being searched for and liked by netizens today. You can Download the Pulling a vacuum to 500 microns files here. Download all free photos and vectors.

If you’re searching for pulling a vacuum to 500 microns images information connected with to the pulling a vacuum to 500 microns keyword, you have visit the right site. Our site frequently gives you suggestions for seeing the highest quality video and picture content, please kindly surf and find more enlightening video content and images that match your interests.

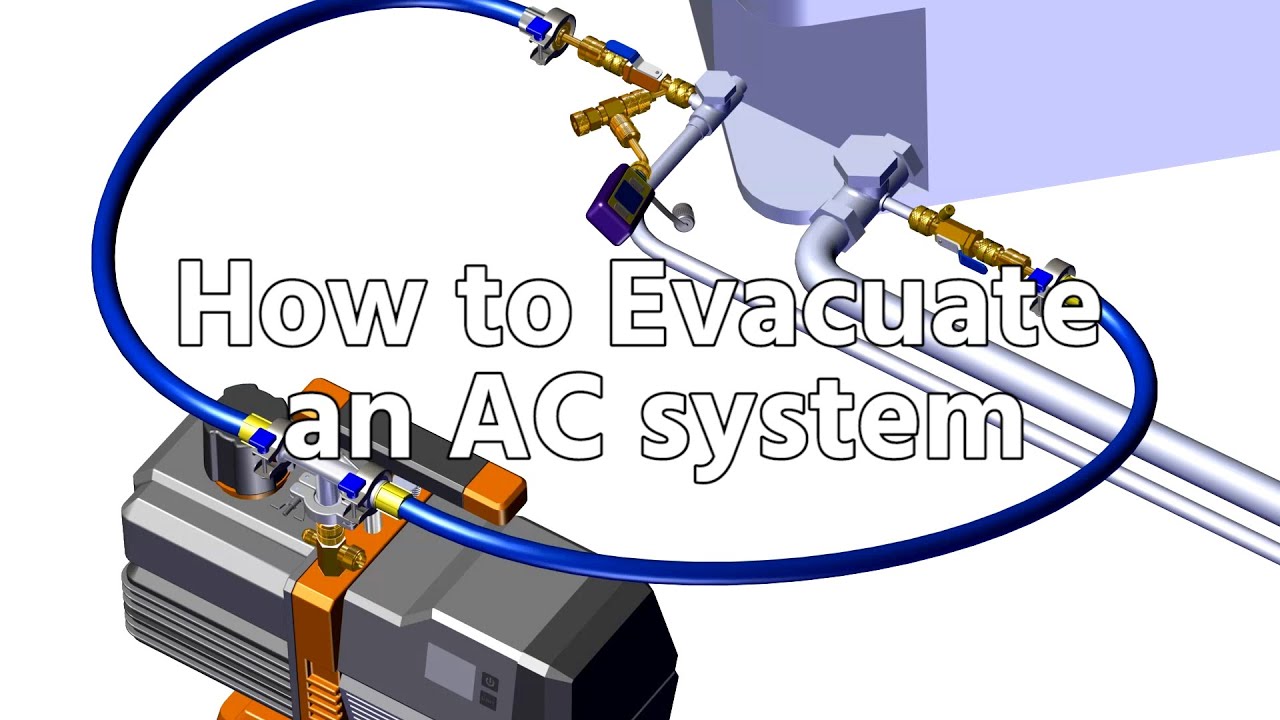

Pulling A Vacuum To 500 Microns. That a manifold is necessary for pulling a deep vacuum. Pulling an efficien. In a refrigerated system the system may need to be lowered in regard to the pressure so that the pressure is lowered to below atmospheric. Pulling below 500 microns and being below 500 microns are two totally different things.

Pin By Erik Fontanez On Hvac Hvac Repair Home Repair Diy Projects From pinterest.com

Pin By Erik Fontanez On Hvac Hvac Repair Home Repair Diy Projects From pinterest.com

If it doesnt your pump oil is contaminated and should be changed. Performing an evacuation on an AC refrigeration system or commercial chiller to below 500 microns is essential to its future performance. You need a better vacuum rig if it takes you 4 days to get to 500 microns even if theres liquid water in it youd get the bulk water out and change the compressor oil in that case anyway before beginning evacuation. In a refrigerated system the system may need to be lowered in regard to the pressure so that the pressure is lowered to below atmospheric. However the term pull a vacuum has another meaning when it refers to refrigeration. He also demonstrated that this is possible with a typical HVAC hookup and that it can pull down to 500 microns with substantial ice present.

How low you pull the vacuum does not.

Some manufacturers test their products down to 20 microns. However it is not very -. If that takes 4 hours because the run is 8 or 2 hours. Pulling below 500 microns and being below 500 microns are two totally different things. An example of a triple evacuation is when you vacuum an empty system down to a certain level such as 1000 microns then break the vacuum with nitrogen to a pressure of 5 PSIG for 5 minutes then vacuum down to 500 microns break the vacuum with nitrogen to a pressure of 5 PSIG for 5 minutes then vacuum down to 200-300 microns. It is common within the industry to set a vacuum target of 500 microns.

Source: thehvachacker.com

Source: thehvachacker.com

Ask to what microns do you pull a vacuum Remember350 microns is the magic number to absolutely guarantee no leaks and removal of all moisture. Close off the ball valves on the core tools and monitor a rise or decay in the pressure on the micron gauge. Then close the CRT valves. If it doesnʼt your pump oil is contaminated and should be changed. Many people say Pull a vacuum to 500 microns and youre good but when I started studying how vacuum works in a system I realized that there was a lot more involved to get the system to 500 microns or lower and to hold that level.

Source: pinterest.com

Source: pinterest.com

Performing an evacuation on an AC refrigeration system or commercial chiller to below 500 microns is essential to its future performance. The sensor in the gauge is too. However it is not very -. You want to hear AT LEAST 500 micronsthis is usually enough to ensure no moisture and an experienced tech will be good enough to install the unit with no leaks. That a manifold is necessary for pulling a deep vacuum.

Some manufacturers test their products down to 20 microns. This is called deep evacuation method. This is called vacuum decay After at least 10 minutes of isolation the system pressure should remain under 500 microns. When servicing an existing system especially when the entire system including. Pulling below 500 microns and being below 500 microns are two totally different things.

Source: pinterest.com

Source: pinterest.com

As an example a small pump with bigger hoses on it will get the job done faster than having a large pump with small hoses. Problems Vacuum Pumping Refrigerant Lines to the 500 Micron Level for HVAC - YouTube. You need a better vacuum rig if it takes you 4 days to get to 500 microns even if theres liquid water in it youd get the bulk water out and change the compressor oil in that case anyway before beginning evacuation. Ask to what microns do you pull a vacuum Remember350 microns is the magic number to absolutely guarantee no leaks and removal of all moisture. As an example a small pump with bigger hoses on it will get the job done faster than having a large pump with small hoses.

Source: youtube.com

Source: youtube.com

If it doesnʼt your pump oil is contaminated and should be changed. A 500-micron vacuum pulled with a standard charging manifold three hose not four and measured with a micron gauge is equal to 500-microns pulled with a specific vacuum manifold tied to your pump with vacuum rated hoses and vacuum rated valve core tools having removed the valve cores. The pressure in the system will rise slowly. You want to hear AT LEAST 500 micronsthis is usually enough to ensure no moisture and an experienced tech will be good enough to install the unit with no leaks. In a refrigerated system the system may need to be lowered in regard to the pressure so that the pressure is lowered to below atmospheric.

Source: youtube.com

Source: youtube.com

You need a better vacuum rig if it takes you 4 days to get to 500 microns even if theres liquid water in it youd get the bulk water out and change the compressor oil in that case anyway before beginning evacuation. Many technicians have been able to get to 500 microns using a pressure manifold with pressure hoses but it takes longer than necessary to get the job done and wasted time is wasted money. Once the target vacuum has been achieved isolate the system from the pump and observe the micron gauge reading. A 500-micron vacuum pulled with a standard charging manifold three hose not four and measured with a micron gauge is equal to 500-microns pulled with a specific vacuum manifold tied to your pump with vacuum rated hoses and vacuum rated valve core tools having removed the valve cores. In terms of how low to pull a vacuum it is irrelevant.

This is called vacuum decay After at least 10 minutes of isolation the system pressure should remain under 500 microns. He also demonstrated that this is possible with a typical HVAC hookup and that it can pull down to 500 microns with substantial ice present. If it doesnt your pump oil is contaminated and should be changed. The vacuum is then observed for a period of time. Do not shut off the blank-off valve on the pump and expect the gauge to hold a vacuum as the gauge will fall back to atmosphere.

Source: fieldpiece.com

Source: fieldpiece.com

In general on a newly installed residential split system you should be able to pull to a target vacuum of 300 microns or less. As long as your under 500 microns and you hold under a 1000 microns in most cases. However it is not very -. You need a better vacuum rig if it takes you 4 days to get to 500 microns even if theres liquid water in it youd get the bulk water out and change the compressor oil in that case anyway before beginning evacuation. The placement of the gauge the size of the hoses and the size of the pump are all important factors.

Source: co.pinterest.com

Source: co.pinterest.com

However it is not very -. In many cases people want it lowered to about 500 microns. You need a better vacuum rig if it takes you 4 days to get to 500 microns even if theres liquid water in it youd get the bulk water out and change the compressor oil in that case anyway before beginning evacuation. It is common within the industry to set a vacuum target of 500 microns. If it doesnt your pump oil is contaminated and should be changed.

Source: pinterest.com

Source: pinterest.com

If playback doesnt begin shortly try. If it doesnʼt your pump oil is contaminated and should be changed. Ask to what microns do you pull a vacuum Remember350 microns is the magic number to absolutely guarantee no leaks and removal of all moisture. However it is not very -. That a manifold is necessary for pulling a deep vacuum.

Source: accutools.com

Source: accutools.com

As an example a small pump with bigger hoses on it will get the job done faster than having a large pump with small hoses. As long as your under 500 microns and you hold under a 1000 microns in most cases. Ask to what microns do you pull a vacuum Remember350 microns is the magic number to absolutely guarantee no leaks and removal of all moisture. Pulling below 500 microns and being below 500 microns are two totally different things. You need a better vacuum rig if it takes you 4 days to get to 500 microns even if theres liquid water in it youd get the bulk water out and change the compressor oil in that case anyway before beginning evacuation.

Source: fieldpiece.com

Source: fieldpiece.com

If that takes 4 hours because the run is 8 or 2 hours. If it doesnt your pump oil is contaminated and should be changed. The pressure in the system will rise slowly. A good vacuum rig coupled to a large pump can overpower the dehydration process pulling below 500 but not removing the moisture which simply takes time. Do not shut off the blank-off valve on the pump and expect the gauge to hold a vacuum as the gauge will fall back to atmosphere.

Source: youtube.com

Source: youtube.com

Always a good idea to attach a micron gauge to the vacuum pump to make sure the pump pulls down to at least 50 microns. This is called vacuum decay After at least 10 minutes of isolation the system pressure should remain under 500 microns. Always a good idea to attach a micron gauge to the vacuum pump to make sure the pump pulls down to at least 50 microns. If it doesnʼt your pump oil is contaminated and should be changed. Close off the ball valves on the core tools and monitor a rise or decay in the pressure on the micron gauge.

Source: acservicetech.com

Source: acservicetech.com

If the vacuum remains at 500 microns the system is deemed to be leak and moisture free. Problems Vacuum Pumping Refrigerant Lines to the 500 Micron Level for HVAC - YouTube. An example of a triple evacuation is when you vacuum an empty system down to a certain level such as 1000 microns then break the vacuum with nitrogen to a pressure of 5 PSIG for 5 minutes then vacuum down to 500 microns break the vacuum with nitrogen to a pressure of 5 PSIG for 5 minutes then vacuum down to 200-300 microns. A fast sharp rise may indicate a leak in the system and a slow gradual rise that flattens may indicate further evacuation must performed as contaminants still. When servicing an existing system especially when the entire system including.

If playback doesnt begin shortly try. Then close the CRT valves. However it is not very -. That a manifold is necessary for pulling a deep vacuum. A 500-micron vacuum pulled with a standard charging manifold three hose not four and measured with a micron gauge is equal to 500-microns pulled with a specific vacuum manifold tied to your pump with vacuum rated hoses and vacuum rated valve core tools having removed the valve cores.

Source: pinterest.com

Source: pinterest.com

Then close the CRT valves. You need a better vacuum rig if it takes you 4 days to get to 500 microns even if theres liquid water in it youd get the bulk water out and change the compressor oil in that case anyway before beginning evacuation. Once the target vacuum has been achieved isolate the system from the pump and observe the micron gauge reading. The placement of the gauge the size of the hoses and the size of the pump are all important factors. Close off the ball valves on the core tools and monitor a rise or decay in the pressure on the micron gauge.

Ask to what microns do you pull a vacuum Remember350 microns is the magic number to absolutely guarantee no leaks and removal of all moisture. You need a better vacuum rig if it takes you 4 days to get to 500 microns even if theres liquid water in it youd get the bulk water out and change the compressor oil in that case anyway before beginning evacuation. Make sure the technician actually owns a micron gauge called a. When you vacuum something up you are sucking up the debris into the vacuum. After reaching 200-300 microns the standing vacuum.

Source: yumpu.com

Source: yumpu.com

A fast sharp rise may indicate a leak in the system and a slow gradual rise that flattens may indicate further evacuation must performed as contaminants still. It is common within the industry to set a vacuum target of 500 microns. If it doesnʼt your pump oil is contaminated and should be changed. Make sure the technician actually owns a micron gauge called a. He also demonstrated that this is possible with a typical HVAC hookup and that it can pull down to 500 microns with substantial ice present.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site beneficial, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title pulling a vacuum to 500 microns by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.